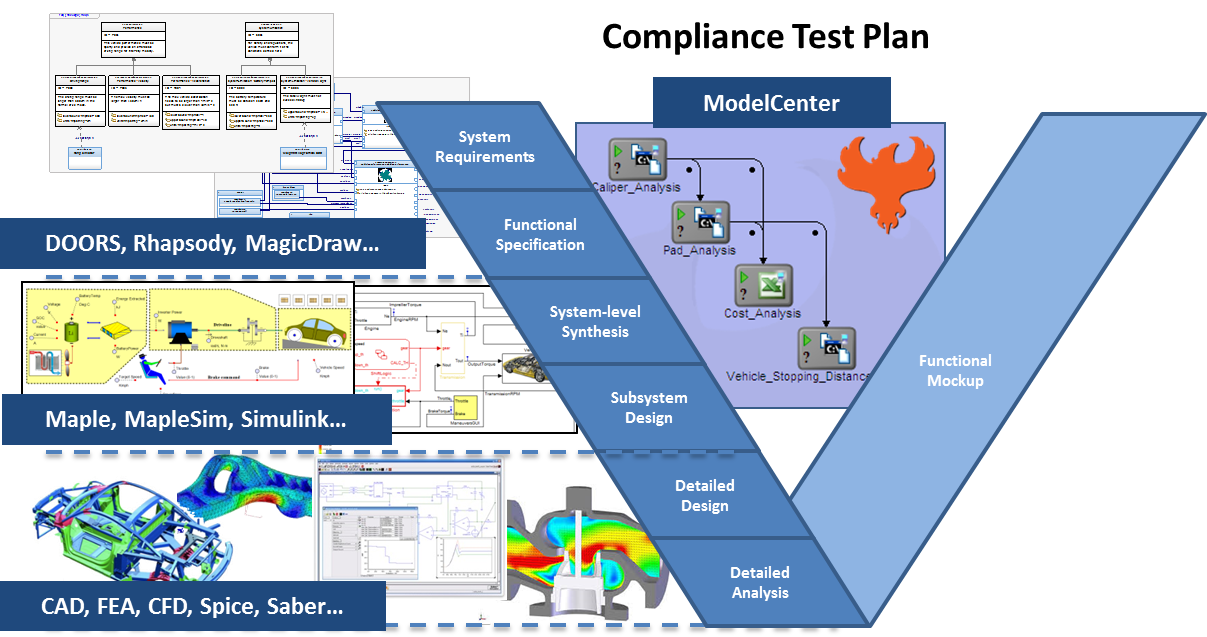

Creation, maintenance, and validation of requirements and systems models

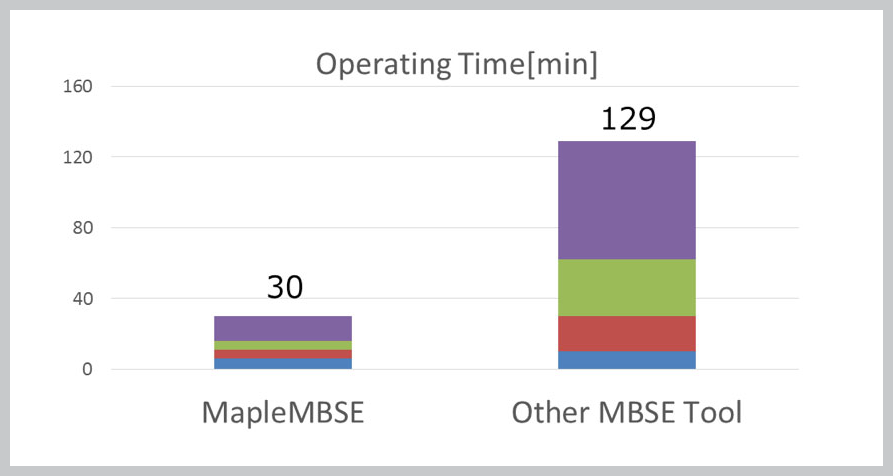

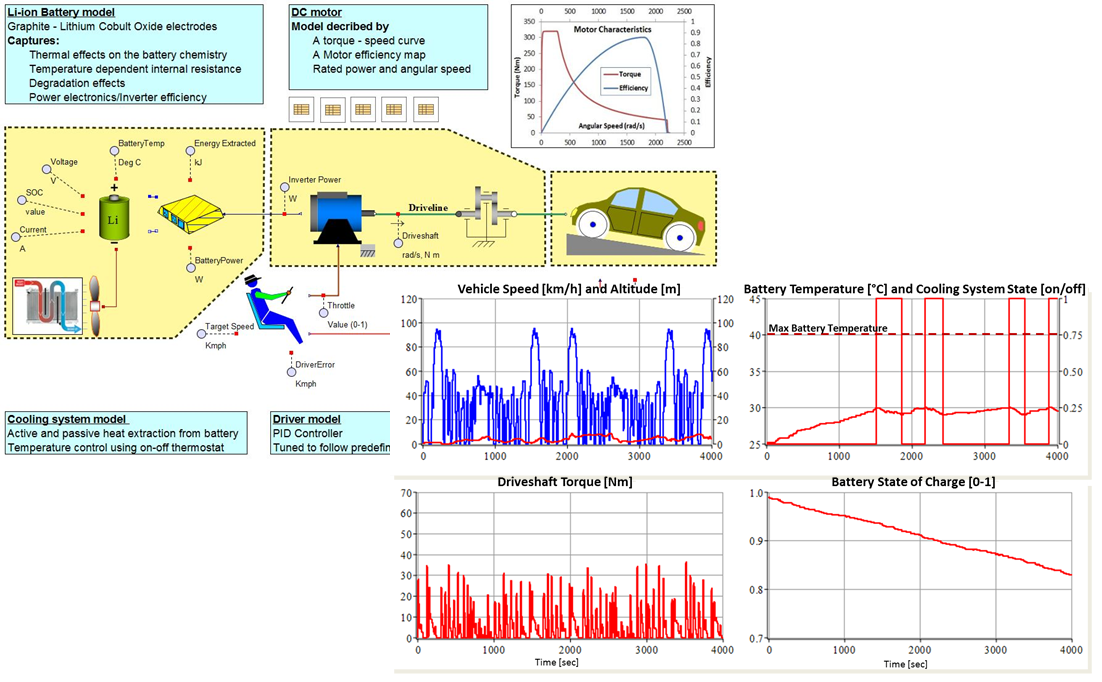

In the world of Model Based Systems Engineering, specialized tools help define high-level system requirements that are used throughout the design chain. Most engineers don't have the training needed to use these complex tools, but their input into system requirements remains vital. With customization by the Maplesoft Engineering Solutions team to meet your specific needs, MapleMBSE makes collaboration on requirements accessible to all stakeholders, providing streamlined interfaces for each task in your MBSE project. By giving more engineers an easy connection to MBSE tools, you can work faster, reduce errors, and ensure a system-wide collaboration on your next project.