It is now possible for many organizations to adopt virtual commissioning techniques for their machine design projects. They may use virtual commissioning to reduce their commissioning time, to reduce commissioning costs, or to create a more reliable time to market. While the applications and specifics may vary, a typical virtual commissioning process has many commonalities.

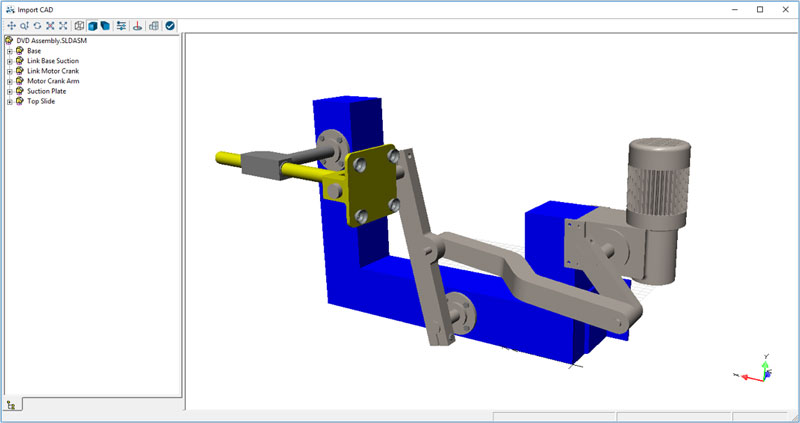

To begin, a model-based Digital Model is constructed using a system-level modeling tool. This is developed either from existing CAD information, or from design concepts that are realized using component libraries. In this workflow, the system-level modeling tool, MapleSim, is used to demonstrate the process of starting from CAD models. Developed by Maplesoft, this tool allows for automatic CAD import so the Digital Model can start with validated geometries. Without a CAD model, engineers can begin by using customizable drag-and-drop components. This is helpful when a project is in the initial idea phase.

1. See how to import and work with your CAD model in MapleSim.

The CAD information can be grouped such that the parts that move together are fused to create aggregate components. This process maintains the fidelity, but simplifies the subsequent modelling (e.g. all the inertias of the bolts, bearings, etc. are accounted for, but are now lumped into the main body to which they are attached). These components can be used together with all other standard and custom components required during model creation.

Using Virtual Commissioning for a New, Competitive Injection Molding Machine

2. See how to design a motion profile for your model using the 1D Motion Generation app in MapleSim.

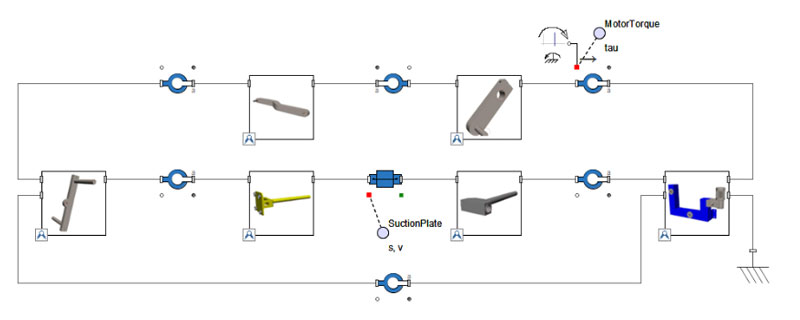

Before connecting the Digital Model to automation software, the simulation software is used to investigate the model and perform a variety of design analyses for functional verification. At this stage, the model can be actuated with a variety of MapleSim’s standard components- hydraulic actuators, electric motors or pre-defined motion profiles.

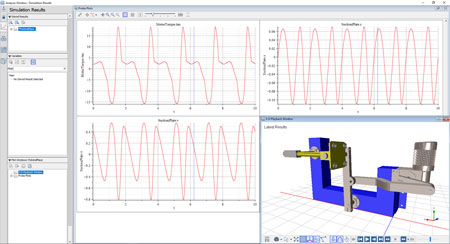

The mechanism’s response to these actuations can then be further analysed. MapleSim provides built-in apps for automating parameter sweeps or Monte Carlo analysis (to view the effects or gauge the sensitivity of your design to specific parameters), but also provides a full programming environment to let you build your own custom analysis.

5. See how to maximize the cycles per minute (CPM) of a pick and place mechanism using MapleSim.

After performing some analysis on the proposed design, the engineer can now size the required motors to choose from their own catalogue of available parts. For engineers working with B&R-supplied tools, they can use MapleSim to generate information for direct use within SERVOsoft.

6. See how to prepare simulation results in MapleSim for motor sizing within B&R's SERVOsoft.

For engineers working with Rockwell Automation hardware and software, they can use MapleSim to generate information for direct use within Motion Analyzer.

The amount of fidelity required for a Digital Model fully depends on the requirements for simulation. A higher fidelity model requires more effort to create, but can answer specific design questions, and offer a more realistic representation of performance for PLC validation. In the past, higher fidelity models were too difficult to create, or couldn’t be used when hardware validation required real-time simulation performance. MapleSim produces code that is optimized for simulation speed, allowing high fidelity Digital Twins that can be useful for a variety of virtual commissioning requirements.

Model inputs are defined by parametrising the system for the virtual commissioning process. Motion paths and loading are defined with design requirements, using the inverse kinematic equations available through MapleSim’s analysis features. These details form an important part of defining the inputs to the model which are maintained when the model is exported as an FMU.

The automation software can now perform a variety of virtual commissioning tasks that would otherwise have waited until physical commissioning. Since both the plant model and PLC code are in a virtual environment, engineers can perform simulations on a large scale, allowing for iterations that test the PLC code in various scenarios. Engineers can look for bugs in their code that may cause slowdowns, performance issues, or safety concerns that would compromise the functioning of the physical system. When engineers discover performance issues, they can be diagnosed with a transparency difficult to obtain during physical commissioning.

Another technique used in this stage is to replace the virtual PLC code with the PLC hardware. Because of the requirements of real-time simulation, this was previously inaccessible for many situations that required a high fidelity model. Engineers can now test the physical hardware against the virtual model, providing another technique to debug issues before constructing the physical system.

While neither of these techniques will eliminate the risk involved in the physical commissioning process, they can serve as resource-efficient techniques to isolate issues earlier in the design process. Unlike, physical commissioning, virtual commissioning can be run as a concurrent process alongside many other tasks in a design project. Since testing can begin while both the plant and controller are in a virtual state, the cost of design iterations is minimal.