For machine-builders working in automation, Virtual Commissioning provides a virtual environment to complete the checks and final control tests, without harming equipment or operators. The simulation uses virtual replicas of the system’s components, making it cheap and effective to make corrections or try out different configuration options.

The physical commissioning process can be costly, unpredictable and time consuming. Whether you are creating a new product or making modifications to an existing design, virtual commissioning has the following benefits:

-

Build better products

Take the guesswork out of machine design by using virtual prototypes for simulation-based motor sizing, PLC code testing, motion profiles and more -

Align your product design with your control strategy

Develop optimized control code by rapidly testing different strategies against a virtual machine model. -

Bring forward the timeline for controller testing

Identify control issues much earlier in the development cycle when they are much easier and less expensive to correct. - Produce a virtual testbed for your control code

Safely identify and address code or motion path errors without impacting hardware or operators.

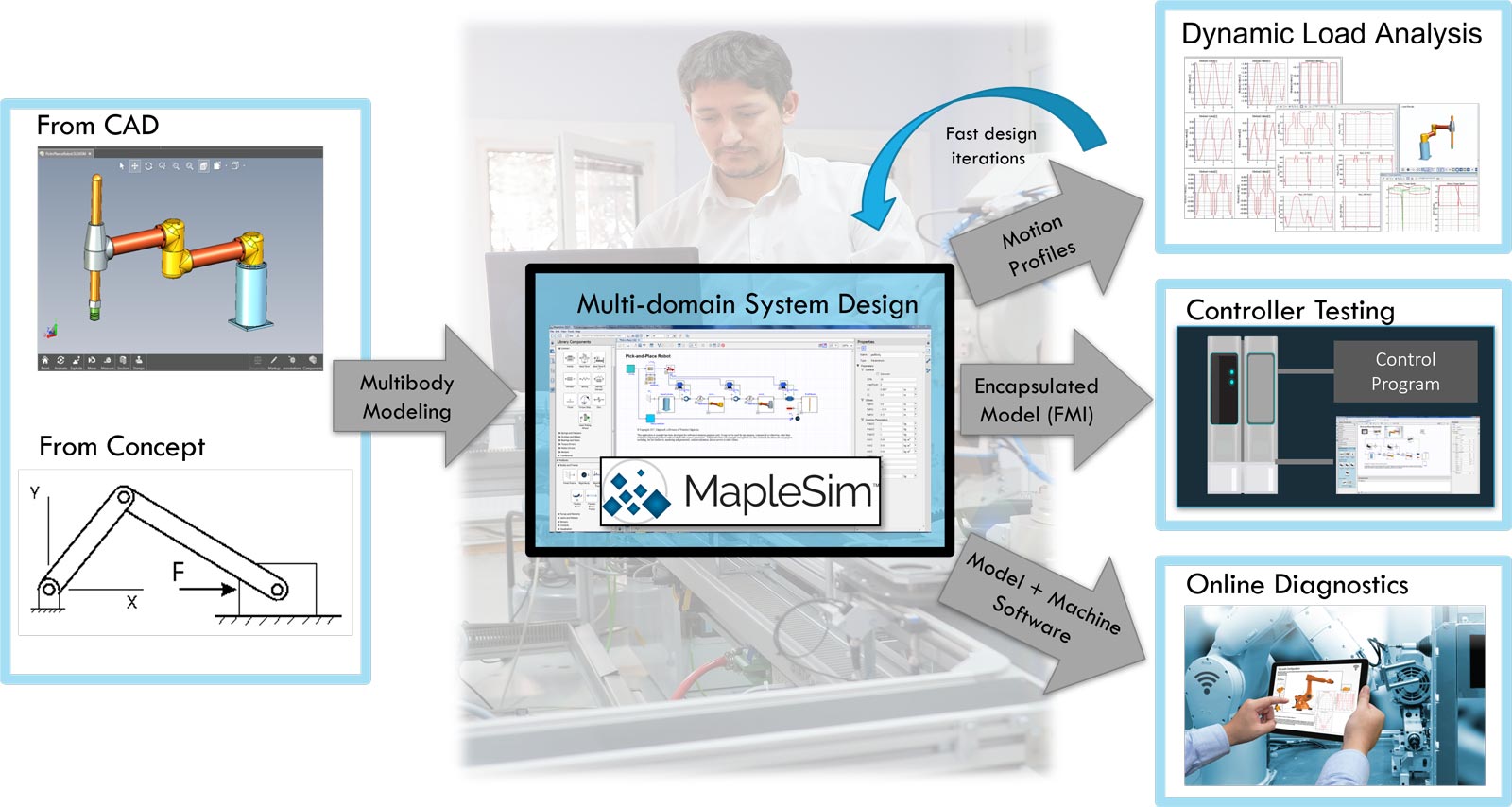

The MapleSim virtual modeling environment saves you significant time across multiple stages of the product commissioning process, leading to faster delivery, less errors, reduced rework – and lower costs!

- SAVE TIME when building a model - MapleSim can import from CAD or using pre-built system-level components, saving time in creating your first model

- SAVE TIME when evaluating design concepts – MapleSim simulations can run through a variety of operating scenarios in minutes before you lock in on the final physical design

- REDUCE ERRORS when checking motion paths – MapleSim and MapleSim Insight can provide visual 3D plots of the machine dynamics and motion profiles, eliminating collision paths before going to production

- SAVE TIME testing and validating control code using a virtual machine – MapleSim models can be used to speed up control strategy testing before applying software updates to the production line

- REDUCE ERRORS by using Digital Twins for Online Diagnostics – Connecting MapleSim models to a cloud-based digital twin platform can be used to detect performance anomalies in a fleet of machines

Using Virtual Commissioning for a New, Competitive Injection Molding Machine