Optimize your control systems and boost performance through Virtual Commissioning

Physical Commissioning vs Virtual Commissioning

When launching a product, after design and development is completed, the commissioning phase is when the product elements are all fitted together with the supporting systems, and the final version is prepared for launch.

For automation products, Physical Commissioning involves operational checks and testing the product alongside the PLC code. At this point hardware and software resources are locked in, making it expensive to make any changes.

In comparison, Virtual Commissioning provides a virtual environment to complete the checks and final control tests, without harming equipment or operators. The simulation uses virtual replicas of the system’s components, making it cheap and effective to make corrections or try out different configuration options.

How does it work?

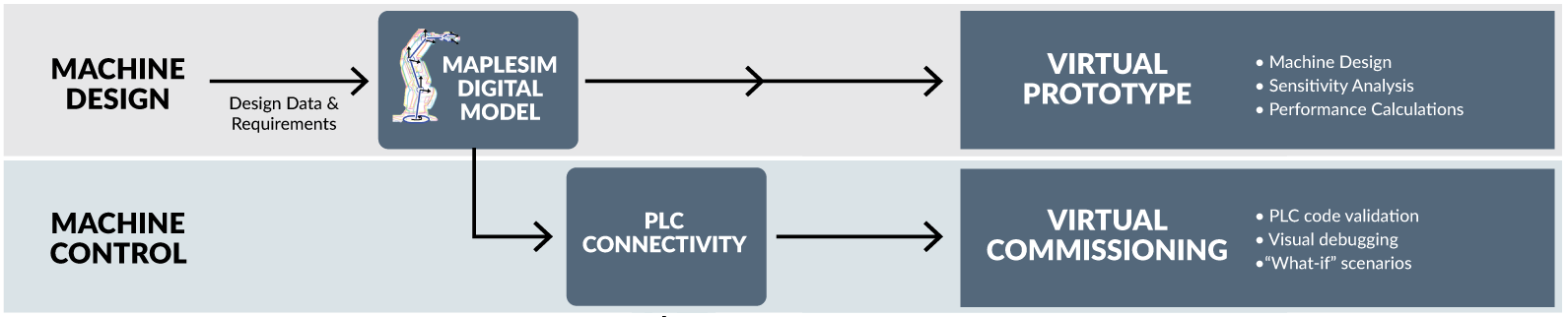

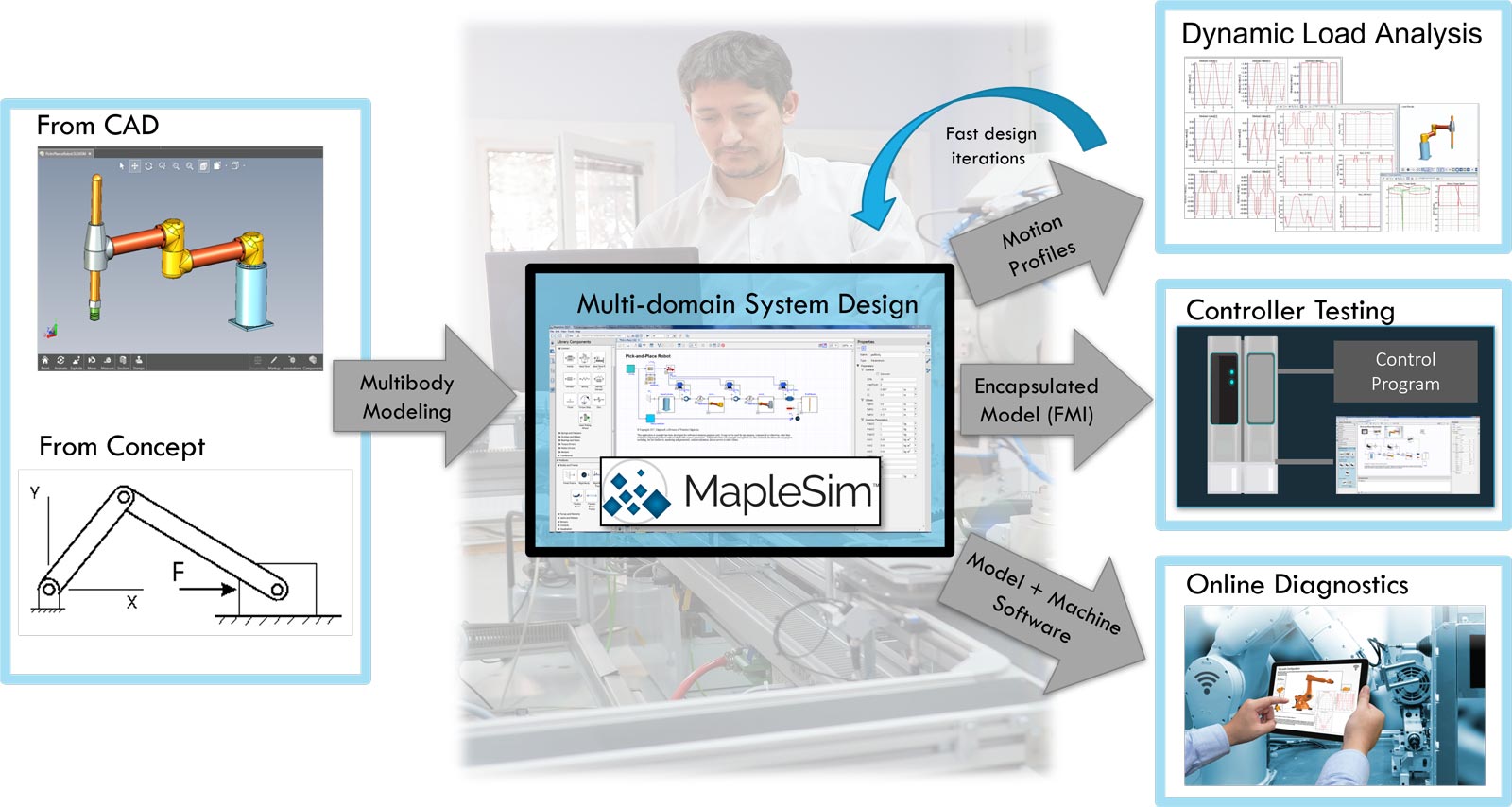

With MapleSim, virtual commissioning of a machine’s dynamics combines three important pieces:

The success of virtual commissioning relies on the seamless integration of the model using MapleSim’s PLC Connectivity options.

The physical commissioning process can be costly, unpredictable and time consuming. Whether you are creating a new product or making modifications to an existing design, virtual commissioning has the following benefits:

Maplesoft's full-service solutions make it easy to implement virtual commissioning, so you can use this powerful approach to diagnose, fix, and optimize machine performance.

Our Turnkey Solutions provide a simple path to machine simulation - no previous modeling experience required!

Expand your modeling capabilities into specialist fields with the MapleSim add-on libraries

Maplesoft Engineering Solutions can provide you with expertise and technology to meet your project requirements quickly. Professional services include product design validation and optimization; code development for in-the-loop simulations; analysis & design calculation tools; and customized training.

Turnkey solutions from Maplesoft Engineering Solutions offer a low-effort way to test out virtual commissioning for your own projects by fast-tracking delivery of an initial model – no previous modeling expertise is required.