Highlights:

- In the effort to drive fuel efficiency of their vehicles, automotive manufacturers are looking beyond the engine to the transmission for optimization of system architectures

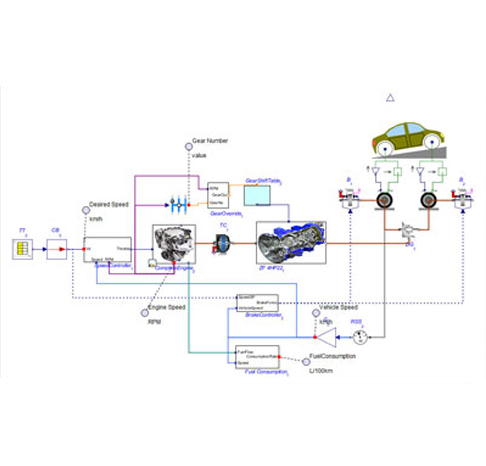

- By modeling and simulating the transmission, a company can accelerate design of a new transmission system while decreasing the number and cost of physical prototypes

As automotive manufacturers strive to improve the fuel efficiency of their vehicles, much of the focus is on the engine as the primary source of power loss. However, there is as much loss through the transmission. Engineers are putting tremendous effort into determining exactly how much power is lost and what can be done to reduce losses and improve overall efficiency. As a result, the transmission industry is now actively involved in optimizing existing designs and exploring new system architectures.

Transmission modeling and simulation provide a means of reducing the number of physical prototypes that must be built during the design of a transmission. At a requirements level this translates into choosing the number and ratio of the gears that will be in a particular design, given a vehicle's target dynamic performance, production cost, and fuel economy.