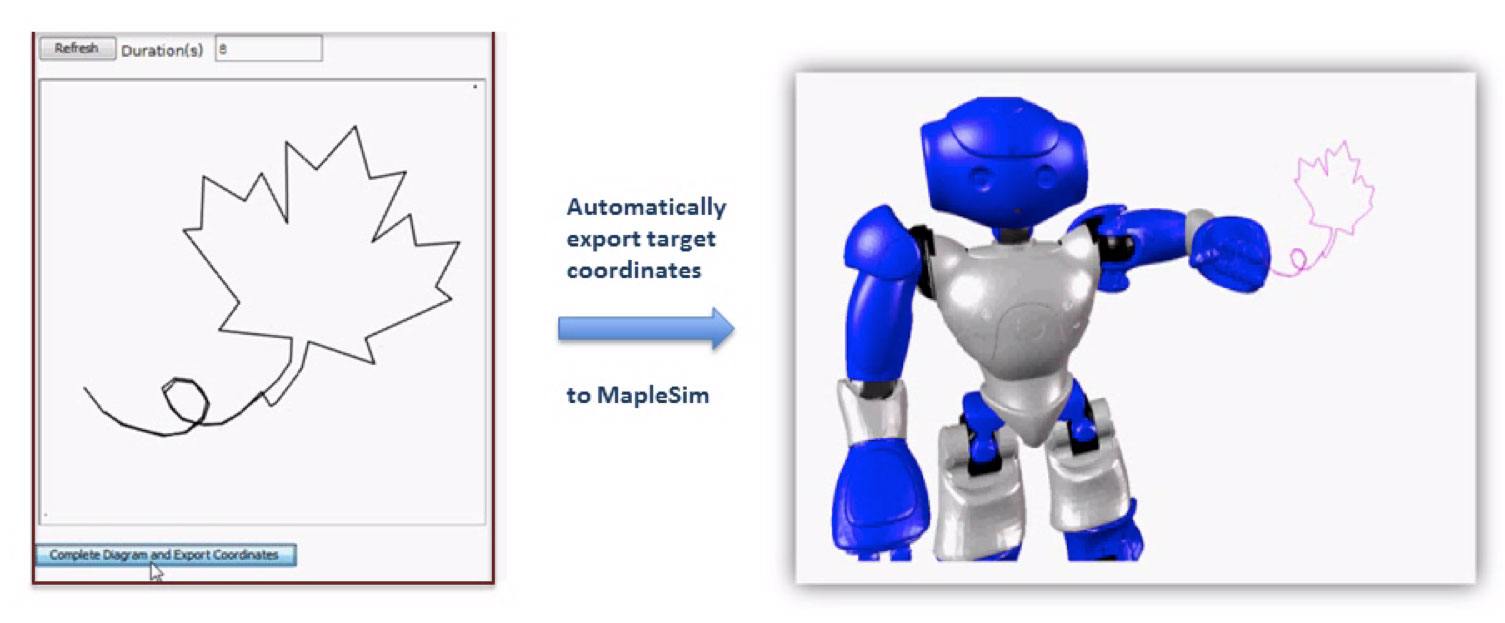

User Case Study:

Modeling the Nao Robot in MapleSim

Applying modern techniques to dramatically reduce model development time, providing greater insight into system behavior, and producing fast, high-fidelity simulations