User Case Study:

Using Maple for Data-Driven Insights in Biotech

Challenge

In the field of industrial bioprocesses, operational data is becoming an increasingly valuable tool to optimize and improve every aspect of a given process. The large amounts of data gathered from these processes helps companies monitor, estimate, and control their processes with a high amount of precision. For these companies, however, finding the right technology to analyze this data can often pose a challenge.

Solution

To properly understand and analyze the large amounts of data in different biological processes, Consibio decided to use Maple for their Industrial Internet of Things (IIoT) platform Monesco. As a spin-out from Aarhus University, Consibio used Maple’s calculation management environment to provide the Monesco platform with analytical capabilities that deliver insight to their customers.

Result

The resulting Monesco IIoT platform now provides insight from over 150 deployed devices, and uses the analysis from Maple to deliver high quality insight for each deployment. The team at Consibio also use Maple to document and report on their processes, taking advantage of the extensive formatting features that Maple provides.

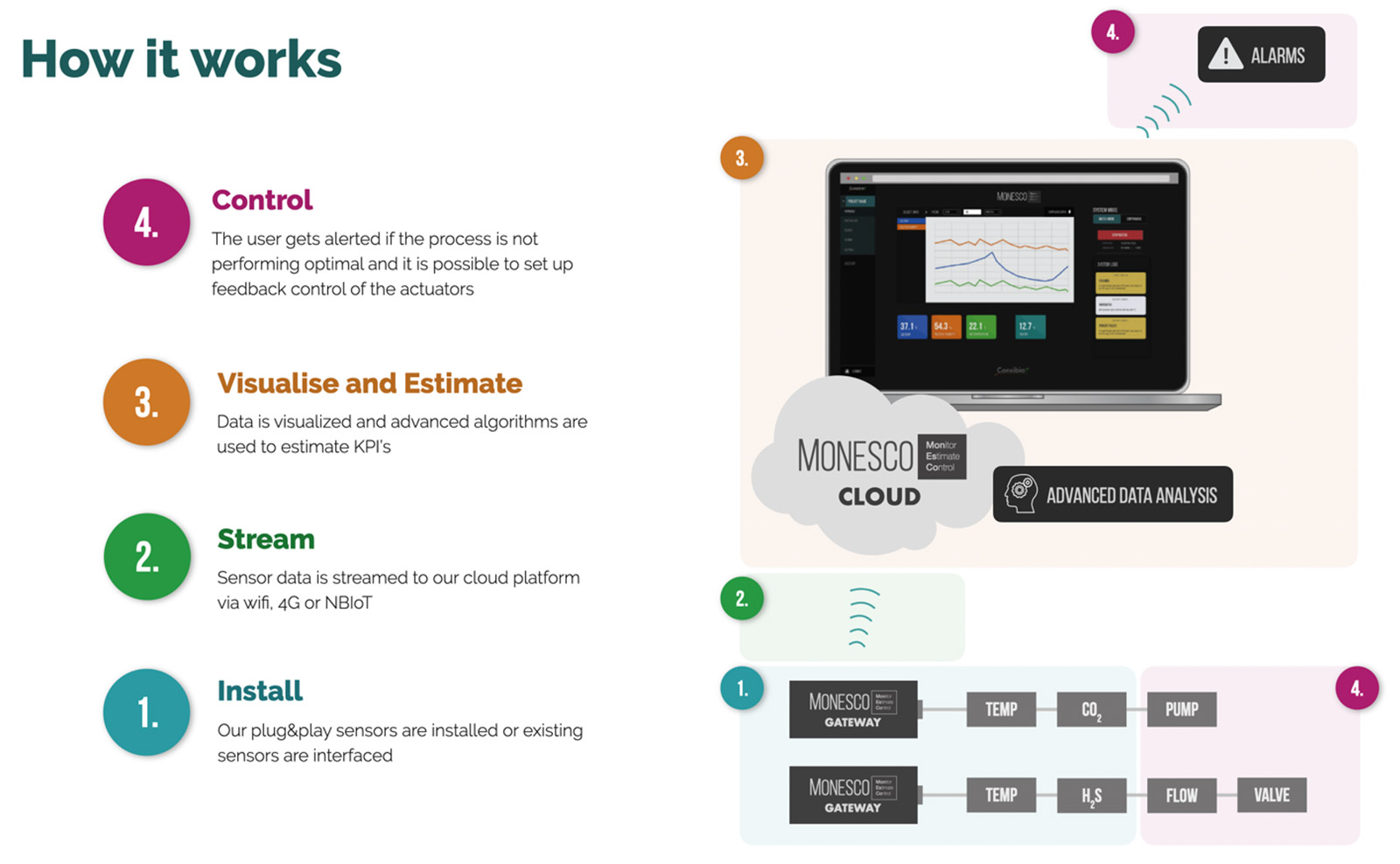

Consibio is a spinout company from Aarhus University School of Engineering, who have developed an Industrial Internet of Things (IIoT) platform called Monesco. As a hardware and software IIoT platform, this platform has been tailored to Monitor, estimate and control (Monesco) industrial bioprocesses.

Consibio’s customers work within the fields of biogas, wastewater treatment, insect production, and research laboratories. Common for all of these industries is the increasing need for data-driven insights, which can be highly difficult to obtain when dealing with complex biological systems for production purposes.

The Monesco platform provides increased accessibility and insight into these bioprocesses through classical real-time monitoring and automation, and also through advanced analysis tools, such as virtual sensor technology. Monesco provides these insights for their customers through an online, web-based platform, and through a smartphone application through the Monesco Cloud.

To achieve the complexity of analysis for these biological processes, Consibio chose Maple, the calculation management tool from Maplesoft, to perform and document their calculations. Maple provides Consibio with a world-class mathematics solver which can account for the multiple data streams that need to be modeled in biological processes. By taking advantage of Maple’s documentation abilities, Consibio is also able to easily track, monitor, and share their calculations for review, which is a key consideration when monitoring the accuracy of their work.

Consibio provides Monesco to companies that are involved in a wide range of biological processes. These customers use Monesco for many tasks, from dimensioning of processes, to incorporating virtual sensors.

Figure 1: The Monesco IIoT platform, developed by Consibio, uses Maple to provide data-driven insight to industrial biological process, such as biogas, wastewater treatment, and more.

Dimensioning of Process Designs

With the chemical and biotechnological engineering expertise at Consibio, they provide deep, domain specific engineering insights in addition to the services associated with the Monesco platform.

Consibio is often calculating and dimensioning process equipment for the needs of their clients. As an example, this could be to calculate the required size of an orifice in a gas pipe system, where the Monesco system is used to measure flow rates based on real-time measurements of differential pressure over the orifice. Here, Consibio uses Maple worksheets as calculation templates, where only the specific parameters are changed from setup to setup, which streamlines workflows for both Consibio and their clients.

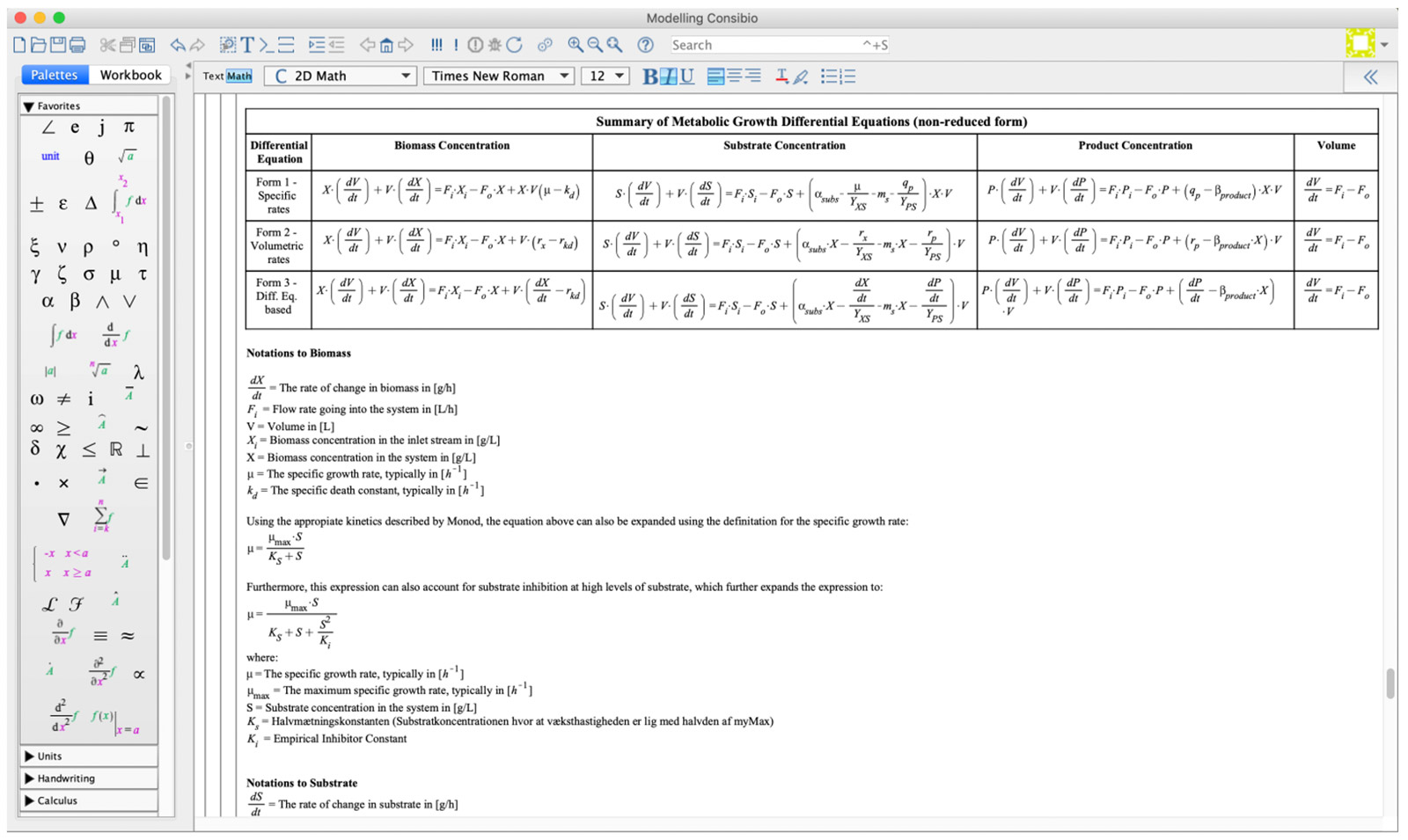

Figure 2: Consibio uses Maple for modeling various biological processes, taking advantage of Maple's intuitive calculation interface.

As another example, Consibio provides dimensioning of heaters and actuators for various production processes. Here, Maple allows Consibio to calculate and visualize the energy and material flows related to dimensioning of equipment for our customers.

Since Consibio is a spinout company from Aarhus University School of Engineering, they have been accustomed to the workflows within Maple, and are able to leverage their expertise to deliver powerful analysis for their clients. Engineers at Consibio considered other mathematical tools for their Monesco platform, but decided that Maple offered the ideal mix of calculation ability and documentation features – both of which are necessary to develop and communicate their insights.

Virtual Sensors

Consibio is also using Maple to obtain more insight into the complex biological production systems by using their virtual sensor technology.

A virtual sensor continuously estimates important key performance indicators (KPIs) that cannot be measured directly, based on a combination of measured process parameters (e.g. temperature, CO2-emission, pH, and so on) and mathematical models that are solved in real-time to correlate these parameters.

Since the biological processes of Consibio’s customers are inherently complex by nature, they are also notoriously difficult to model and predict. With the help of their virtual sensor technology, Consibio can present their customers with crucial process parameters and business KPIs. With this information, customers can increase their product throughput, decrease their greenhouse gas emissions or improve their production.

When developing the mathematical models used as the foundation for these virtual sensors, Consibio uses Maple to describe, derive, visualize, and solve the coupled differential equations that describe the physical biochemical processes involved in production. Consibio uses Maple for these models, taking advantage of Maple’s analytical strengths and prebuilt analysis tools. When evaluating other tools, Consibio was not confident that they could implement solutions as quickly or robustly as they could by using Maple.

Figure 3: Engineers from Consibio demonstrating their IIoT platform, Monesco.

Sharing Insights for Customers and Partners

A core value at Consibio is to present data and insights for their customers and project partners in simple formats that are easy to understand by stakeholders. Maple allows Consibio to have advanced mathematical calculations and user-friendly presentations in the same environment, creating a live link between presentations and calculations. Consibio first uses Maple as calculation tool to solve complex mathematical problems for their clients, who require precise models for their biological process. Once these calculations are complete, Consibio continues to use Maple for presenting their results to customers. By using Maple as both a calculation and presentation platform, Consibio can speed up their development, reduce their chances of transcription errors, and can update their calculations in real time when providing reporting and visualizations to their customers and partners.

Contact Maplesoft to learn how Maple can help with your projects.

Contact Maplesoft to learn how Maple can help with your projects.