|

Joel and Dr. Weinstein at work |

Context:

When Joel Segre graduated from Stanford’s School of Engineering, his goal was to design medical devices that would be affordable to over four billion people in the world who earn under $2 a day. Blindness, in particular, appealed to him as a good place to start as it was both a cause and effect of poverty. Those too poor to pay for vision care go blind. Those blinded by lack of vision care become poor.

Working at a non-profit organization dedicated to making medical technology and health care services accessible and affordable, Segre found the opportunity to follow up on his goal. Specifically, he worked in the area of cataracts, which account for around 75% of preventable blindness worldwide.

Cataracts are easily treated with intraocular lenses, which replace the diseased tissues of the eye in a simple procedure. In much of the developing world, however, intraocular lenses produced in the developed countries are prohibitively expensive at around $100 a piece. Segre hoped to design an equivalent lens at a fraction of the cost.

Problem:

Using precision machining equipment, Segre came up with several early prototype lenses. However, many of them produced images with a light haze unacceptable for use in humans. Segre could not identify the problem and struggled to understand where the error occurred. Segre turned for help to his step-father, Dr. Marvin Weinstein, a well-known theoretical physicist at the Stanford Linear Accelerator Center.

|

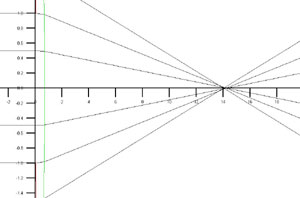

Failure to focus is just visible at the

cross over point |

|

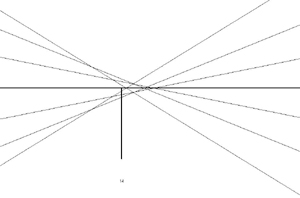

Zoomed in view of aberration |

Solution:

Dr. Weinstein considered the problem and suggested that in order to understand the cause of the haze they would have to develop a stronger intuition for how sub-micron variations in the optical surfaces of each lens would affect image quality. To answer the question, Dr. Weinstein decided to construct a computer model of each lens and ray-trace the expected image. In this way they would be able to modify the shape of the lens quickly and see what variations were causing the problem. While there are expensive ray-tracing programs for designing lenses on the market, Dr. Weinstein, a long time Maple user, decided to implement a simple ray-tracing program in Maple. (This program is available on the Maplesoft web site: Ray Tracing Package ). When the known lens shape was put into this program, Dr. Weinstein was able to identify the cause of the problem and help Segre correct it. Dr. Weinstein’s computation proved a critical turning point in the lens design process.

“I knew Maple was ideal in this context,” said Dr. Weinstein. “Maple graphics were well suited for the task and its mix of symbolic and numerical calculation ability, together with the ability to use the document interface to manipulate the resulting images, created a program that was powerful and simple to use. When Joel asked me for a solution, Maple was the first program that came to my mind. And it lived up to its reputation.”

Reflecting on the success of the project, Segre said “The ray tracing package in Maple allowed Marvin to whip out a solution to a problem that was literally keeping me up at night. Based on Marvin’s calculations, I went back to the lab and fixed the problem. Our lenses now produce crystal clear images, which will mean higher visual acuity for the people who need it most.”

Contact Maplesoft to learn how Maple can be used for your projects

Contact Maplesoft to learn how Maple can be used for your projects